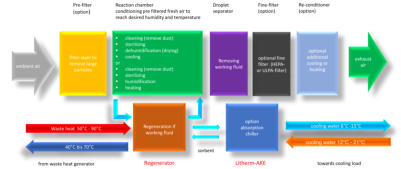

Litherm-TEK requires electrical power only for the circulation pumps and the control equipment.

The regeneration process use low temperature - “waste heat“ like

•

process waste heat

•

engine waste heat

•

solar or geothermic heat

•

waste heat from combined heat and power production

•

heat from conventional heating systems

Energy supply

Engineering

Litherm-TEK is based on the principle of wet scrubber (VDI 3679) by using a complete new designed

spray-nozzle system developed by FluCoS.

It guarantees a consistant drop size of the absorption fluid over the complete range of load condtions.

The air will be purified from

•

particulates and germs (class U17 according to EN1822:2009 respectively ISO 75 U and ISO 29463:2011)

Depending on customer requirements the system will be able to reach the following air conditions

•

dehumidifiyng down to 15 %rF (min. 1,0 g/kg water content)

•

cooling down to +7

0

C (additional cooling by external heat exchangers possible)

•

heating up to 50

0

C (additional heating by external heat exchangers possible)

•

humidifiyng up to 98 %rF

Based on case of application we use different spray fluids for the process.

The fluids will be constantly regenerated in a circle process by using heat or waste heat.

All fluids used by FluCoS are efficient, reliable, sustainable and save for human and environment.

Address

FluCoS GmbH & Co. KG Hauptstraße 24 D-97941 TauberbischofsheimPhone

Tel.: +49(0)9341 - 89 69 554 Fax: +49(0)9341 - 89 69 552

Select your language